1. GAMBARAN UMUM TENTANG ISA S 5.1

Tujuan standar ini adalah untuk menetapkan cara yang seragam untuk menentukan instrumen dan sistem instrumentasi yang digunakan untuk pengukuran dan kontrol. Untuk tujuan ini, sistem penunjukan yang mencakup simbol dan kode identifikasi disajikan.

Cakupan Aplikasi

Cara-cara yang dibutuhkan untuk

memberikan informasi mengenai operasi proses oleh berbagai pengguna bisa

berbeda-beda, maka perlu mengenal standar simbol agar dapat menggambarkan dan

menjelaskan apa yang diinginkan pengguna mengenai instrumentasi

- Aplikasi Industri

Standar simbol instrumen banyak

digunakan di industri chemical, petroleum, power generation, air conditioning,

dan proses lndusttri lainnya seperti astronomy, navigation, and medicine, yang menggunakan instrumen

yang sangat khusus

-

Applikasi untuk aktifitas

pekerjaan

Standar

sangat cocok untuk digunakan pada sistem control dan instrumen untuk maksud melambangkan

dan identifikasi yang diperlukan pengguna seperti

• Design sketches

• Teaching examples

• Technical papers,

literature, and discussions

• Instrumentation system

diagrams, loop diagrams, logic diagrams

• Functional descriptions

• Flow diagrams: Process,

Mechanical, Engineering, Systems, Piping (Process) and Instrumentation

• Construction drawings

• Specifications, purchase

orders, manifests, and other lists

• Identification (tagging)

of instruments and control functions

• Installation, operating

and maintenance instructions, drawings, and records

Standar

dimaksudkan untuk memberikan informasi kepada seseorang meninjau beberapa

dokumen mengenai proses pengukuran dan kontrol, untuk mengetahui maksud dari

pengukuran dan pengontrolan proses

- Aplikasi untuk kelas instrumentasi dan fungsi instrumen

Metode simbol dan

identifikasi dalam standar ini dapat dipakai untuk semua tingkatan pengukuran

proses dan instrumen kontrol. Ini juga digunakan tidak hanya untuk

menggambarkan instrumen-instrumen diskrit dengan fungsinya, tetapi juga untuk

menggambarkan fungsi-fungsi sistem analog yang bervariasi misal bagian-bagian

display, kontrol, distributed control, dan computer control.

- Tingkat identifikasi fungsional

Standar ini menyediakan identifikasi dan simbolisasi fungsi-fungsi utama suatu instrumen. Rincian tambahan dari instrumen lebih baik dijelaskan dalam spesifikasi yang sesuai, lembar data, atau dokumen lain yang ditujukan bagi mereka yang membutuhkan detail tersebut.

-

Extent of loop identification

The standard covers the

identification of an instrument and all other instruments or control

functions associated with it

in a loop. The user is free to apply additional identification — by

serial number, unit number,

area number, plant number, or by other means.

2 DEFINISI

Untuk maksud lebih mengerti

tentang standar ini berikut ini beberapa istilah yang digunakan:

Accessible: A term applied to a device

or function that can be used or be seen by an operator for the purpose of

performing control actions, e.g., set point changes, auto-manual transfer, or

on-off actions.

Alarm: A device or function that

signals the existence of an abnormal condition by means of an audible or

visible discrete change, or both, intended to attract attention. It is not

recommended that the term alarm switch or alarm be used to designate a device

whose

operation is simply to close

or open a circuit that may or may not be used for normal or abnormal interlock,

start-up, shutdown, actuation of a pilot light or an alarm device, or the like.

The first device is properly designated as a level switch, a flow switch, etc.,

because "switching" is what the device does. The device may be

designated as an alarm only if the device itself contains the alarm function. [See also Table 1, note

(13).]

Assignable: A term applied to a feature

permitting the channeling (or directing) of a signal from one device to another

without the need for switching, patching, or changes in wiring.

Auto-manual station: Synonym for control

station.

Balloon: Synonym for bubble.

Behind the panel: A term applied to a

location that is within an area that contains (1) the instrument panel, (2) its

associated rack-mounted hardware, or (3) is enclosed within the panel. Behind

the panel devices are not accessible for the operator's normal use, and are not

designated as local or front-of-panel-mounted. In a very broad sense,

"behind the panel" is equivalent to "not normally accessible to

the operator."

Binary: A term applied to a signal

or device that has only two discrete positions or states. When used in its

simplest form, as in "binary signal" (as opposed to "analog

signal"), the term denotes an "on-off" or "high-low"

state, i.e., one which does not represent continuously varying quantities.

Board: Synonym for panel.

Bubble: The circular symbol used

to denote and identify the purpose of an instrument or

function. It may contain a

tag number. Synonym for balloon.

Computing device: A device or function that

performs one or more calculations or logic operations, or both, and transmits

one or more resultant output signals. A computing device is sometimes called a

computing relay.

Configurable: A term applied to a device

or system whose functional characteristics can be

selected or rearranged

through programming or other methods. The concept excludes rewiring as a means

of altering the configuration.

Controller: A device having an output

that varies to regulate a controlled variable in a specified manner. A

controller may be a self-contained analog or digital instrument, or it may be

the equivalent of such an instrument in a shared-control system.

An automatic controller

varies its output automatically in response to a direct or indirect input of a

measured process variable. A manual controller is a manual loading station, and

its output is not dependent on a measured process variable but can be varied

only by manual adjustment. A controller may be integral with other functional

elements of a control loop.

Control station: A manual loading station

that also provides switching between manual and

automatic control modes of a

control loop. It is also known as an auto-manual station. In addition, the

operator interface of a distributed control system may be regarded as a control

station.

Control valve: A device, other than a

common, hand-actuated ON-OFF valve or self-actuated check valve, that directly

manipulates the flow of one or more fluid process streams. It is expected that

use of the designation "hand control valve" will be limited to

hand-actuated valves that (1) are used for process throttling, or (2) require

identification as an instrument.

Converter: A device that receives

information in one form of an instrument signal and transmits an output signal

in another form. An instrument which changes a sensor's output to a standard

signal is properly designated as a transmitter, not a converter. Typically, a

temperature element (TE) may connect to a transmitter (TT), not to a converter

(TY).

A converter is also referred

to as a transducer; however, "transducer" is a completely general term,

and its use specifically for signal conversion is not recommended.

Digital: A term applied to a signal

or device that uses binary digits to represent continuous

values or discrete states.

Distributed control system: A system which, while

being functionally integrated, consists of

subsystems which may be

physically separate and remotely located from one another.

Final control element: The device that directly

controls the value of the manipulated variable of a control loop. Often the

final control element is a control valve.

Function: The purpose of, or an action

performed by, a device.

Identification: The sequence of letters or

digits, or both, used to designate an individual

instrument or loop.

Instrument: A device used directly or

indirectly to measure and/or control a variable. The term includes primary elements,

final control elements, computing devices, and electrical devices such as

annunciators, switches, and pushbuttons. The term does not apply to parts

(e.g., a receiver bellows or a resistor) that are internal components of an

instrument.

Instrumentation: A collection of

instruments or their application for the purpose of observation, measurement,

control, or any combination of these.

Local: The location of an

instrument that is neither in nor on a panel or console, nor is it mounted in a

control room. Local instruments are commonly in the vicinity of a primary

element or a final control element. The word "field" is often used

synonymously with local.

Local panel: A panel that is not a

central or main panel. Local panels are commonly in the

vicinity of plant subsystems

or sub-areas. The term "local panel instrument" should not be

confused with "local

instrument."

Loop: A combination of two or

more instruments or control functions arranged so that signals pass from one to

another for the purpose of measurement and/or control of a process variable.

Manual loading station: A device or function

having a manually adjustable output that is used to actuate one or more remote

devices. The station does not provide switching between manual and automatic

control modes of a control loop (see controller and control station). The

station may have integral indicators, lights, or other features. It is also

known as a manual station or a manual loader.

Measurement: The determination of the

existence or the magnitude of a variable.

Monitor: A general term for an

instrument or instrument system used to measure or sense the status or

magnitude of one or more variables for the purpose of deriving useful

information. The term monitor is very unspecific — sometimes meaning analyzer,

indicator, or alarm. Monitor can also be used as a verb.

Monitor light: Synonym for pilot light.

Panel: A structure that has a

group of instruments mounted on it, houses the operator-process interface, and

is chosen to have a unique designation. The panel may consist of one or more sections,

cubicles, consoles, or desks. Synonym for board.

Panel-mounted: A term applied to an

instrument that is mounted on a panel or console and is accessible for an

operator's normal use. A function that is normally accessible to an operator in

a shared-display system is the equivalent of a discrete panel-mounted device.

Pilot light: A light that indicates

which of a number of normal conditions of a system or device exists. It is

unlike an alarm light, which indicates an abnormal condition. The pilot light

is also known as a monitor light.

Primary element: Synonym for sensor.

Process: Any operation or sequence

of operations involving a change of energy, state, composition, dimension, or

other properties that may be defined with respect to a datum.

Process variable: Any variable property of a

process. The term process variable is used in this standard to apply to all

variables other than instrument signals.

Program: A repeatable sequence of

actions that defines the status of outputs as a fixed relationship to a set of

inputs.

Programmable logic

controller:

A controller, usually with multiple inputs and outputs, that

contains an alterable

program.

Relay: A device whose function is

to pass on information in an unchanged form or in some

modified form. Relay is

often used to mean computing device. The latter term is preferred.

The term "relay"

also is applied specifically to an electric, pneumatic, or hydraulic switch

that is actuated by a signal. The term also is applied to functions performed

by a relay.

Scan: To sample, in a

predetermined manner, each of a number of variables intermittently. The function

of a scanning device is often to ascertain the state or value of a variable.

The device may be associated with other functions such as recording and

alarming.

Sensor: That part of a loop or

instrument that first senses the value of a process variable, and that assumes

a corresponding, predetermined, and intelligible state or output. The sensor

may be separate from or integral with another functional element of a loop. The

sensor is also known as a detector or primary element.

Set point: An input variable that

sets the desired value of the controlled variable. The set point may be

manually set, automatically set, or programmed. Its value is expressed in the

same units as the controlled variable.

Shared controller: A controller, containing

preprogrammed algorithms that are usually accessible, configurable, and

assignable. It permits a number of process variables to be

controlled by a single

device.

Shared display: The operator interface

device (usually a video screen) used to display process control information

from a number of sources at the command of the operator.

Switch: A device that connects,

disconnects, selects, or transfers one or more circuits and is not designated

as a controller, a relay, or a control valve. As a verb, the term is also

applied to the functions performed by switches.

Test point: A process connection to

which no instrument is permanently connected, but which is intended for the

temporary or intermittent connection of an instrument.

Transducer: A general term for a

device that receives information in the form of one or more

physical quantities,

modifies the information and/or its form, if required, and produces a resultant

output signal. Depending on the application, the transducer can be a primary

element, transmitter, relay, converter or other device. Because the term

"transducer" is not specific, its use for specific applications is not

recommended.

Transmitter: A device that senses a

process variable through the medium of a sensor and has an output whose

steady-state value varies only as a predetermined function of the process variable.

The sensor may or may not be integral with the transmitter.

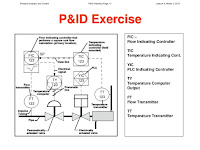

3. SYMBOLS s

1 The examples in this

standard illustrate the symbols that are intended to depict instrumentation on

diagrams and drawings. Methods of symbolization and identification are

demonstrated. The examples show identification that is typical for the pictured

instrument or functional interrelationships.

The symbols indicating the

various instruments or functions have been applied in typical

ways in the illustrations.

This usage/PENGGUNAAN does not imply, however, that the applications or

designations of the instruments or functions are restricted in any way. No

inference should be drawn that the choice of any of the schemes for

illustration constitutes a recommendation for the illustrated methods of

measurement or control. Where alternative symbols are shown without a statement

of preference, the relative sequence of symbols does not imply a preference.

2 The bubble may be used to

tag distinctive symbols, such as those for control valves, when such tagging is

desired. In such instances, the line connecting the bubble to the instrument

symbol is drawn close to, but not touching, the symbol. In other instances, the

bubble serves to represent the instrument proper.

3 A distinctive symbol whose

relationship to the remainder of the loop is easily apparent from a diagram

need not be individually tagged on the diagram. For example, an orifice flange

or a control valve that is part of a larger system need not be shown with a tag

number on a diagram. Also, where there is a primary element connected to

another instrument on a diagram, use of a symbol to represent the primary

element on the diagram is optional.

4 A brief explanatory notation

may be added adjacent to a symbol or line to clarify the function of an item.

For instance, the notations 3-9 psig and 9-15 psig adjacent to the signal lines

to two valves operating in split range, taken together with the symbols for the

failure modes, allow complete understanding of the intent. Similarly, when two

valves are operated in a diverting or mixing mode from a common signal, the

notations 3-15 psig and 15-3 psig, together with the failure modes, allow understanding

of the function.

5 The sizes of the tagging

bubbles and the miscellaneous symbols shown in the examples are the sizes

generally recommended; however, the optimum sizes may vary depending on whether

or not the finished diagram is to be reduced in size and depending on the

number of characters that are expected in the instrument tagging designation.

The sizes of the other symbols may be selected as appropriate to accompany the

symbols of other equipment on a diagram.

6 Aside from the general

drafting requirements for neatness and legibility, symbols may be drawn with

any orientation. Likewise, signal lines may be drawn on a diagram entering or

leaving the appropriate part of a symbol at any angle. However, the function

block designators of Table 3 and the tag numbers should always be drawn with a horizontal

orientation. Directional arrowheads should be added to signal lines when needed

to clarify the direction of flow of information. The judicious use of such

arrowheads, especially on complex drawings, will often facilitate understanding

of the system.

7 The electrical, pneumatic,

or other power supply to an instrument is not expected to be shown unless it is

essential to an understanding of the operation of the instrument or the loop.

8 In general, one signal line

will suffice to represent the interconnections between two instruments on flow diagrams

even though they may be connected physically by more than one line.

9 The sequence in which the

instruments or functions of a loop are connected on a diagram should reflect

the functional logic or information flow, although this arrangement will not

necessarily correspond to the signal connection sequence. Thus, an electronic

loop using analog voltage signals requires parallel wiring, while a loop using

analog current signals requires series interconnections.

However, the diagram in both

instances should be drawn as though all the wiring were

parallel, to show the

functional interrelationships clearly while keeping the presentation

independent of the type of instrumentation finally installed. The correct

interconnections are expected to be shown on a suitable diagram.

10 The degree of detail to be

applied to each document or sketch is entirely at the discretion of the user of

the standard. The symbols and designations in this standard can depict both

hardware and function. Sketches and technical papers will usually contain

highly simplified symbolism and identification. Process flow diagrams will

usually be less detailed than engineering flow diagrams.

Engineering flow diagrams

may show all in-line components, but may differ from user to user in the amount

of off-line detail shown. In any case, consistency should be established for

each application. The terms simplified, conceptual, and detailed as applied to

the diagrams of 6.12 were chosen to represent a cross section of typical usage.

Each user must establish the degree of detail that fulfills the purposes of the

specific document or sketch being generated.

11 It is common practice for

engineering flow diagrams to omit the symbols of interlockhardware components

that are actually necessary for a working system, particularly when symbolizing

electric interlock systems. For example, a level switch may be shown as

tripping a pump, or separate flow and pressure switches may be shown as

actuating a solenoid valve or other interlock devices. In both instances,

auxiliary electrical relays and other components may be considered details to

be shown elsewhere. By the same token, a current transformer sometimes will be

omitted and its receiver shown connected directly to the process — in this case

the electric motor.

12 Because the distinctions

between shared display/shared control and computer functions are sometimes

blurred, in choosing symbols to represent them the user must rely on

manufacturers' definitions, usage in a particular industry, and personal judgment.

4 TABEL

The purpose of Tables, is to define certain of the building

blocks of the identification and symbolic representation system used in this

standard in a concise, easily-referenced manner.

Table 1, Identification Letters,

together with the Notes for Table 1, define and explain the

individual letter

designators used as functional identifiers in accordance with the rules of Functional Identification.

1

Notes for Table 1

1) A "user's

choice" letter is intended to cover unlisted meanings that will be used repetitively

in a particular project. If used, the letter may have one meaning as a

firstletter and another meaning as a succeeding-letter. The meanings need to be

defined only once in a legend, or other place, for that project. For example,

the letter N may be defined as "modulus of elasticity" as a

first-letter and "oscilloscope" as a succeeding-letter.

2) The unclassified letter X

is intended to cover unlisted meanings that will be used only once or used to a

limited extent. If used, the letter may have any number of meanings as a

first-letter and any number of meanings as a succeeding-letter. Except for its

use with distinctive symbols, it is expected that the meanings will be defined

outside a tagging bubble on a flow diagram. For example, XR-2 may be a stress

recorder and XX-4 may be a stress oscilloscope.

3) The grammatical form of

the succeeding-letter meanings may be modified as required.

For example,

"indicate" may be applied as "indicator" or

"indicating," "transmit" as "transmitter" or

"transmitting," etc.

4) Any first-letter, if used

in combination with modifying letters D (differential), F (ratio), M

(momentary), K (time rate of change), Q (integrate or totalize), or any

combination of these is intended to represent a new and separate measured

variable, and the combination is treated as a first-letter entity. Thus,

instruments TDI and TI indicate two different variables, namely,

differential-temperature and temperature. Modifying letters are used when

applicable.

5) First-letter A (analysis)

covers all analyses not described by a "user's choice" letter.

It is expected that the type

of analysis will be defined outside a tagging bubble.

6) Use of first-letter U for

"multivariable" in lieu of a combination of first-letters is optional.

It is recommended that

nonspecific variable designators such as U be used sparingly.

7) The use of modifying

terms "high," "low," "middle" or

"intermediate," and "scan" is optional.

8) The term

"safety" applies to emergency protective primary elements and

emergency protective final control elements only. Thus, a self-actuated valve

that prevents operation of a fluid system at a higher-than-desired pressure by

bleeding fluid from the system is a back-pressure-type PCV, even if the valve

is not intended to be used normally. However, this valve is designated as a PSV

if it is intended to protect against emergency conditions, i.e., conditions

that are hazardous to personnel and/or equipment and that are not expected to

arise normally.

The designation PSV applies

to all valves intended to protect against emergency pressure conditions

regardless of whether the valve construction and mode of operation place them

in the category of the safety valve, relief valve, or safety relief valve. A

rupture disc is designated PSE.

9) The passive function G

applies to instruments or devices that provide an uncalibrated view, such as

sight glasses and television monitors.

10) "Indicate"

normally applies to the readout—analog or digital—of an actual measurement. In

the case of a manual loader, it may be used for the dial or setting indication,

i.e., for the value of the initiating variable.

11) A pilot light that is

part of an instrument loop should be designated by a first-letter followed by

the succeeding-letter L. For example, a pilot light that indicates an expired time

period should be tagged KQL. If it is desired to tag a pilot light that is not

part of an instrument loop, the light is designated in the same way. For

example, a running light for an electric motor may be tagged EL, assuming

voltage to be the appropriate measured variable, or YL, assuming the operating

status is being monitored. The unclassified variable X should be used only for

applications which are limited in extent.

The designation XL should

not be used for motor running lights, as these are commonly numerous. It is

permissible to use the user's choice letters M, N or O for a motor running

light when the meaning is previously defined. If M is used, it must be clear

that the letter does not stand for the word "motor," but for a

monitored state.

12) Use of a

succeeding-letter U for "multifunction" instead of a combination of

other functional letters is optional. This nonspecific function designator

should be used sparingly.

13) A device that connects,

disconnects, or transfers one or more circuits may be either a switch, a relay,

an ON-OFF controller, or a control valve, depending on the application. If the

device manipulates a fluid process stream and is not a hand-actuated ON-OFF

block valve, it is designated as a control valve. It is incorrect to use the

succeeding-letters CV for anything other than a self-actuated control valve.

For all applications other than fluid process streams, the device is designated

as follows:

• A switch, if it is

actuated by hand.

• A switch or an ON-OFF

controller, if it is automatic and is the first such device in a loop.

The term "switch" is generally used

if the device is used for alarm, pilot light, selection,

interlock, or safety.

• The term "controller"

is generally used if the device is used for normal operating control.

• A relay, if it is

automatic and is not the first such device in a loop, i.e., it is actuated by a

switch or an ON-OFF controller.

14) It is expected that the

functions associated with the use of succeeding-letter Y will be defined

outside a bubble on a diagram when further definition is considered necessary.

This definition need not be made when the function is self-evident, as for a

solenoid valve in a fluid signal line.

15) The modifying terms

"high," and "low," and "middle" or

"intermediate" correspond to values of the measured variable, not to

values of the signal, unless otherwise noted. For example, a high-level alarm

derived from a reverse-acting level transmitter signal should be an LAH, even

though the alarm is actuated when the signal falls to a low value. The terms

may be used in combinations as appropriate.

16) The terms

"high" and "low," when applied to positions of valves and

other open-close devices, are defined as follows: "high" denotes that

the valve is in or approaching the fully open position, and "low"

denotes that it is in or approaching the fully closed position.

17) The word

"record" applies to any form of permanent storage of information that

permits

retrieval by any means.

18) For use of the term

"transmitter" versus "converter," .

19) First-letter V, "vibration or mechanical analysis," is intended to perform the duties in machinery monitoring that the letter A performs in more general analyses. Except for vibration, it is expected that the variable of interest will be defined outside the tagging bubble.

20) First-letter Y is

intended for use when control or monitoring responses are eventdriven

as opposed to time- or time

schedule-driven. The letter Y, in this position, can also signify presence or

state.

21) Modifying-letter K, in

combination with a first-letter such as L, T, or W, signifies a time rate of

change of the measured or initiating variable. The variable WKIC, for instance,

may represent a rate-of-weight-loss controller.

22) Succeeding-letter K is a

user's option for designating a control station, while the succeeding-letter C

is used for describing automatic or manual controllers.

2 Comments

This comment has been removed by the author.

ReplyDeleteI truly delighted in perusing your article. I found this as an instructive and curiously post, so i think it is exceptionally valuable and learned. I would like to thank you for the exertion you have got made in composing this article. Digital as built p&ids Vancouver, BC

ReplyDelete