Explain air intake filter house in details?

Gas turbines consume large mass of air

a 125 MW machine has compressor inlet flow of 438 kg/s for 50 oC ambient temperature

thus careful design of the intake system is needed to ensure that:

frictional losses are a minimum, and

noise of the air entering the machine is kept to an acceptable limit.

Explain air intake filter house in details?

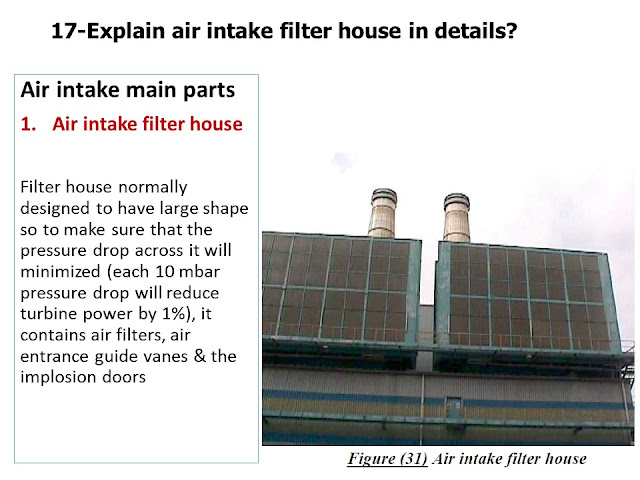

Air intake main parts

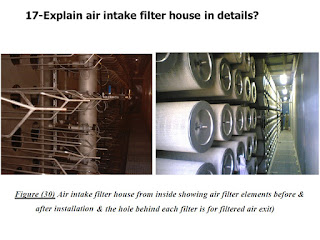

Filter element

Air entering compressor must be filtered from any dust or residues that may enter & cause fouling to the which reduce compressor blades efficiency, the use of series of filters in stead of one big filter is more practical because design & erection complexity are reduced, also if pressure drop in air intake increases, a set of small filters can easily be removed in stead of removing the hall big filter.

Air intake silencer

The silencer contain sound absorbent baffles & these baffles are covered with perforated sheets & filled with high quality heat & moisture resistance mineral wool, this mineral wool is covered by a glass fiber which gives an additional mechanical protection for the absorbent material.

Air intake main parts

Filter element purging system

As air passes through filter elements for a long period, the filters become dirty & thus the pressure drop across them will increase, to overcome rapid increase in pressure drop either filter elements is replaced with new elements or air filter must be purged

The compressed air will released via small holes on the air lines located behind each filter ,there are solenoid valves that operate with respect to each raw of filters to release that compressed air.

Compressed air releasing process will done by pulsing ,so some time filters cleaning system may named as pulse air system ,complete purging process may take 84 pulses (30 minutes duration ) & the cleaning process will start from top of the air intake to the bottom so that we avoid dust to sucked again by upper filter raw.

Gas turbines consume large mass of air

a 125 MW machine has compressor inlet flow of 438 kg/s for 50 oC ambient temperature

thus careful design of the intake system is needed to ensure that:

frictional losses are a minimum, and

noise of the air entering the machine is kept to an acceptable limit.

Explain air intake filter house in details?

Air intake main parts

Filter element

Air entering compressor must be filtered from any dust or residues that may enter & cause fouling to the which reduce compressor blades efficiency, the use of series of filters in stead of one big filter is more practical because design & erection complexity are reduced, also if pressure drop in air intake increases, a set of small filters can easily be removed in stead of removing the hall big filter.

Air intake silencer

The silencer contain sound absorbent baffles & these baffles are covered with perforated sheets & filled with high quality heat & moisture resistance mineral wool, this mineral wool is covered by a glass fiber which gives an additional mechanical protection for the absorbent material.

Air intake main parts

Filter element purging system

As air passes through filter elements for a long period, the filters become dirty & thus the pressure drop across them will increase, to overcome rapid increase in pressure drop either filter elements is replaced with new elements or air filter must be purged

The compressed air will released via small holes on the air lines located behind each filter ,there are solenoid valves that operate with respect to each raw of filters to release that compressed air.

Compressed air releasing process will done by pulsing ,so some time filters cleaning system may named as pulse air system ,complete purging process may take 84 pulses (30 minutes duration ) & the cleaning process will start from top of the air intake to the bottom so that we avoid dust to sucked again by upper filter raw.

0 Comments